Research

The main research lines of CAMMS group can be explained with the research projects in which it has been recently involved.

FIBREGY

Development, engineering, production and life-cycle management of improved FIBRE-based material solutions for structure and functional components of large offshore wind enerGY and tidal power platform. Project funded from the European Union’s Horizon 2020 program under grant agreement No 952966. Project running from January 2021 to December 2023.

The main objective of the FIBREGY project is to enable the extensive use of FRP materials in the structure of the next generation of large Renewable Energy Offshore Platforms (REOPs). In order to achieve this objective, the project will develop, qualify and audit innovative FRP materials for offshore applications, elaborate new design procedures and guidelines, generate efficient production, inspection and monitoring methodologies, and validate and demonstrate advanced software analysis tools.

ECO-COMPASS

Ecological and Multifunctional Composites for Application in Aircraft Interior and Secondary Structures. Project Funded under Horizon 2020, International cooperation in aeronautics with China (Call H2020-MG-1.10-2015) running from April 2016 to Mars 2019.

The main aim of the project is to develop and assess multifunctional and ecologically improved composites from bio-sourced and recycled materials for application in aircraft secondary structures and interior. CAMMS coordinates the work package related to the numerical characterization of the new composite materials developed in the framework in the project. For this project the group developed multiscale models to characterize biocomposites, and coupled them with optimization procedures in order to obtain the best composite architecture for a given structural application.

ASHVIN

ASsistants for Healthy, safe, and productive Virtual construction design, operation & maintenance using a digital twIN. Project founded from de European Union’s Horizon 2020 research and innovation program under grant agreement No 958161. Project running from September 2020 to September 2023.

This project aims at enabling the European construction industry to significantly improve its productivity, while reducing cost and ensuring absolutely safe work conditions, by providing a proposal for a European wide digital twin standard, an open source digital twin platform integrating IoT and image technologies, and a set of tools and demonstrated procedures to apply the platform and the standard proven to guarantee specified productivity, cost, and safety improvements. CAMMS role consists of implementing methods for digital twin based structural monitoring and asset management, establishing real-time connection between physical infrastructures and realistic numerical models, and combining structural health monitoring technologies with multi-physics numerical models and predictive maintenance tools.

FATIGUE4LIGHT

Fatigue modelling and fast testing methodologies to optimize part design and to boost lightweight materials deployment in chassis parts, Project funded from the European Union’s Horizon 2020 program under grant agreement No 101006844. Project running from February 2021 to January 2024.

Fatigue4Light project aims to investigate lightweight solutions adapted to the chassis part of EV to reach a 24-30% weight reduction. This will give a 12-15% weight saving from structural vehicle weight, and also increase EV safety due to reduced sprung mass. Solutions will be based on the introduction of especially developed material solutions with high fatigue performance (AHSS, stainless steel, Al alloys and hybrid metal-FRP materials), the development of new computer modelling with high fatigue prediction accuracy and new experimental methodologies that reduce the testing time. Sustainability of the proposed solutions will be continuously considered along project through an eco-design general approach. Attention will be given to manufacturing processes (cutting and welding) to improve the knowledge on their effect to the overall fatigue performance of chassis components. CAMMS group is leading the consortium and is in charge of the fatigue modelling on chassis components.

FIBRESHIP

Engineering, production and life-cycle management for massive application of FIBRE-based materials in large-length SHIPs. Project funded from the European Union’s Horizon 2020 research and innovation program under grant agreement No 723360. Project running from June 2017 to May 2020.

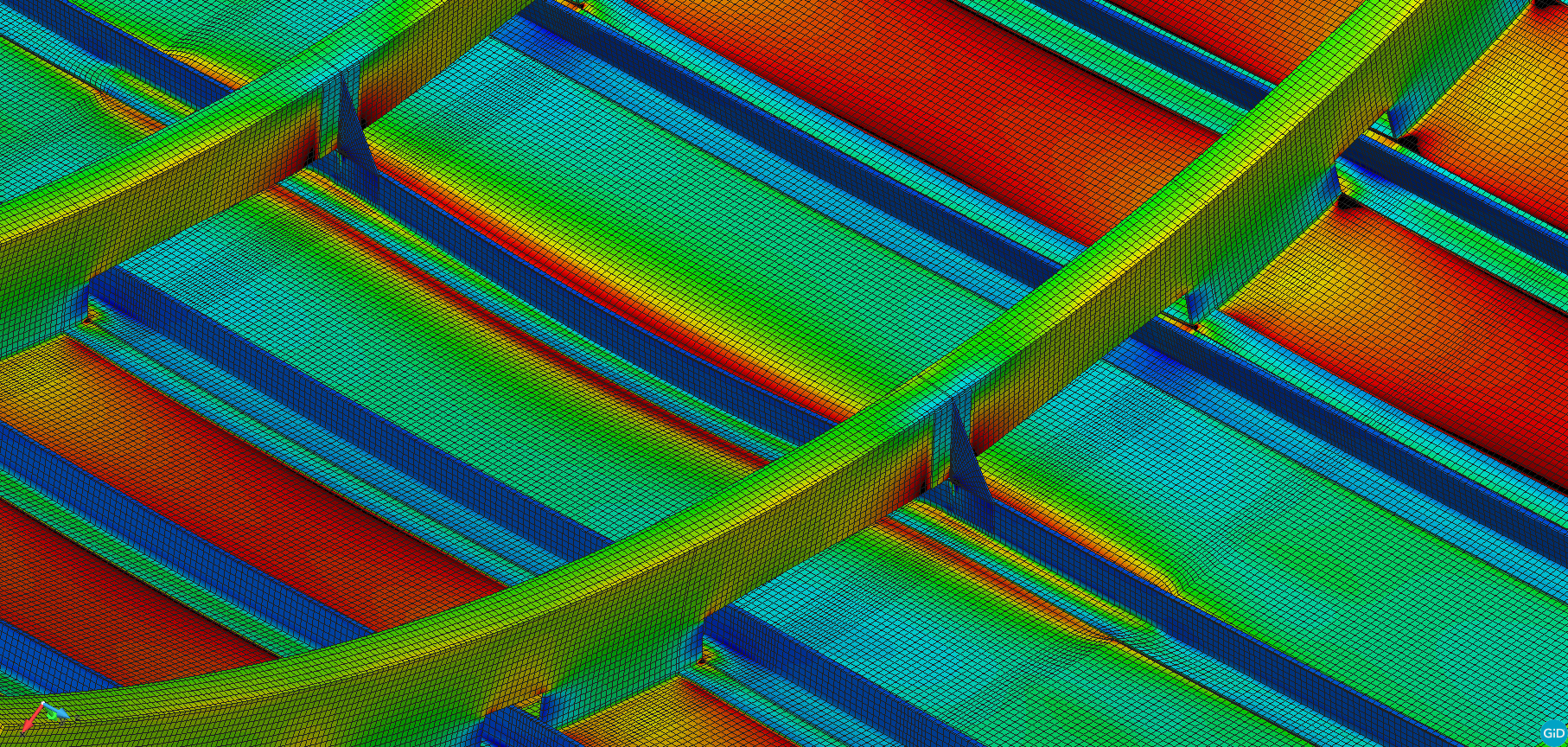

The main aim of Fibreship project is to develop the required technologies for designing and constructing large length ships made of composites. CAMMS role in Fibreship consists on developing numerical models especially suited for the analysis of fibreship required composite materials, accounting for strength failure and fatigue, and their incorporation into FEM packages for the analysis of fibreships. CAMMS will also develop models to assess the fire performance of composites and to characterize the connections between composite parts.

FIBRE4YARDS

FIBRE composite manufacturing technologies FOR the automation and modular construction in shipYARDS. Project funded from the European Union’s Horizon 2020 program under grant agreement No 952966. Project running from January 2021 to December 2023.

The main objective of FIBRE4YARDS is to maintain European global leadership in ship building and ship maintenance, through implementation of the Shipyard 4.0 concept in which advanced and innovative FRP manufacturing technologies are successfully introduced. FIBRE4YARDS focuses on the entire value chain of the shipyards and their ecosystem, cooperatively working on small and medium length fibre-based ships in a digital environment. CAMMS group will develop models for the analysis of pultrusion beams, 3D printed materials, thermoplastics and composite connections.

The overall objective of ACASIAS is to contribute to the reduction of energy consumption of future aircraft by developing advanced concepts for aerostructures with multifunctional capabilities. ACASIAS intends to embed sensors and antennas into typical structures of aircraft (for instance fuselage panels, winglets and tails). CAMMS is in charge of developing most of the numerical models of the multifunctional structures to be developed, which will help to obtain an optimized design.

ACASIAS

Advanced Concepts for Aero-Structures with Integrated Antennas and Sensors. Project funded from the European Union’s Horizon 2020 research and innovation program under grant agreement No 723167. Project running from June 2017 to November 2020.

ANAV

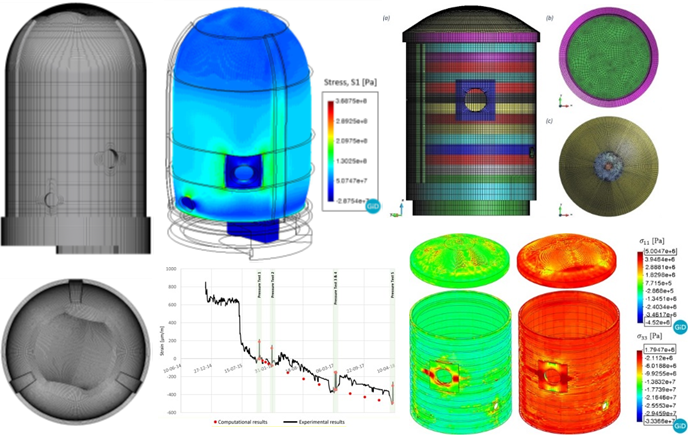

Study on the structural behaviour of the Vandellos II, Asco I and Asco II nuclear plants throughout the estimated service life funded by ANAV, S.A. from 01/09/2016 to 31/06/2018.

The study included the assessment of the internal failure pressure due to accident with damage to the nucleus for the Ascó I, Ascó II y Vandellós II nuclear containment structures as well as the reassessment of the ultimate capacity of the Ascó I y Ascó II nuclear plants after the re-stressing of the steel tendons that have their average stress below the limit design stress level.

CAMMS group was in charge of the development and implementation of a numerical formulation able to account for pre/post stressing effects for any kind of steel tendon trajectory. Overseeing the mesh generation and calibration of material data for the simulation. Overseeing the nonlinear structural simulations. Overseeing the reporting tasks. Development of on-demand post-processes functionalities inside the FEM code as required by the client.